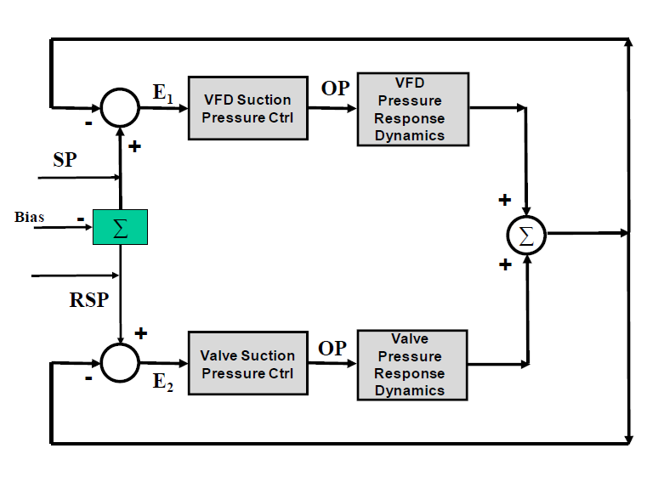

High process variability compromises the economic performance of SAGD processes through off-quality products and reduced process efficiency. Upgrading controller tuning, control valve response, and control strategies are relatively easy pathways to reducing variability on key SAGD loops, thereby improving overall process performance. Improving the troubleshooting skills of process control personnel is another pathway to improved performance via quick and effective responses to control loop problems.

The course is conducted at a hotel conference facility. The class size is limited to 8 students.

Topics covered include:

- Process Variability

- Process Dynamics

- Control Loop Performance

- Impact of Process Design

- Identifying Process Variability

- Attenuating Disturbances

- Troubleshooting Loop Problems

- Managing Process Variability

Tyler Rushfeldt, P.Eng. has over 10 years’ experience across various aspects of the pipeline industry, notably steady state and transient hydraulics and currently specializing in pressure control applications

Doug Nelson has over 30 years of pulp and paper process control experience. He has authored papers on paper machine dryer control, control valve selection and the uses of process simulation in optimization surveys.

No records found.

This four-day course is intended to strengthen the student's ability to optimize process performance.

The first half of the course focuses on improving control loop performance. The measurement of process dynamics and Lambda tuning are the key topics.

The second half of the course focuses on troubleshooting techniques, and management approaches to maintaining a low variability operation.

SAGD process and control systems are used throughout the lectures to illustrate the course concepts. Approximately 30% of the course is devoted to a simulation lab where the course concepts are practised.

The course is primarily intended for process engineers, instrumentation engineers, and operations management personnel who want to improve their ability to troubleshoot process control and variability problems. The course explores the implications of process equipment and therefore would be beneficial for maintenance and design engineers.

The course is being held at a conference facility. Attendees are responsible for arranging their own accommodations.

For convenience, we recommend that registrants stay at the hotel course site.