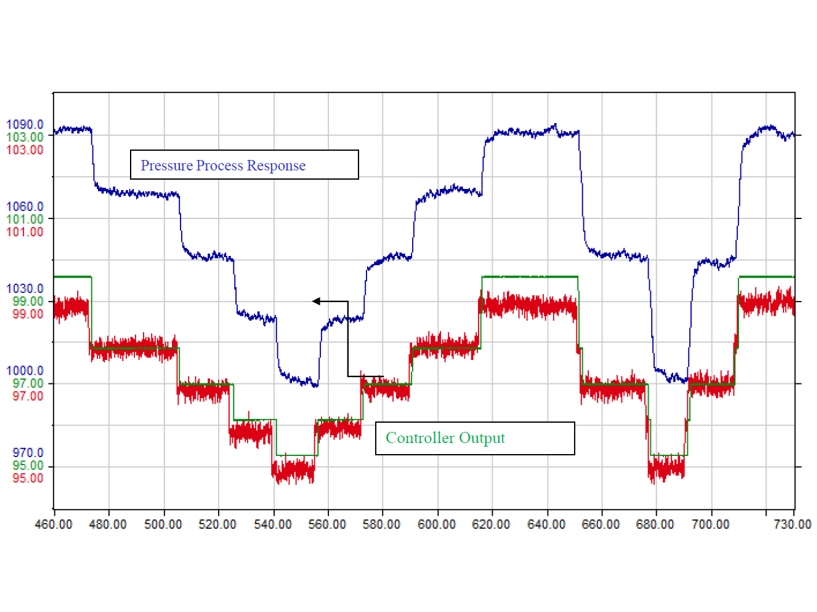

Pipeline system pressure and flow control applications are somewhat unique. The pipeline control valves may spend much of their time wide open to minimize pumping costs but also need to respond quickly and accurately to sudden pressure excursions to prevent unscheduled line shutdowns.

One key to ‘good’ pipeline control is careful selection and sizing of the process control equipment (sensors, pumps, valves) in order to ensure fast and controllable dynamics. Good control strategy design and a structured, scientific approach to control loop tuning are essential components to achieving performance and variability objectives. The ability to identify and solve process and control problems quickly and reliably requires an analytical troubleshooting approach.

The course is conducted by video conference. The class size in the video conference format is limited to 8 students.

Topics covered include:

- Pressure Control Strategies

- Override, Split Ranging, Linearization

- Flow control applications

- Interacting control loops

- Viscosity / Density Control

- Ratio, Cascade, Feedforward

- Lambda Tuning advanced strategies

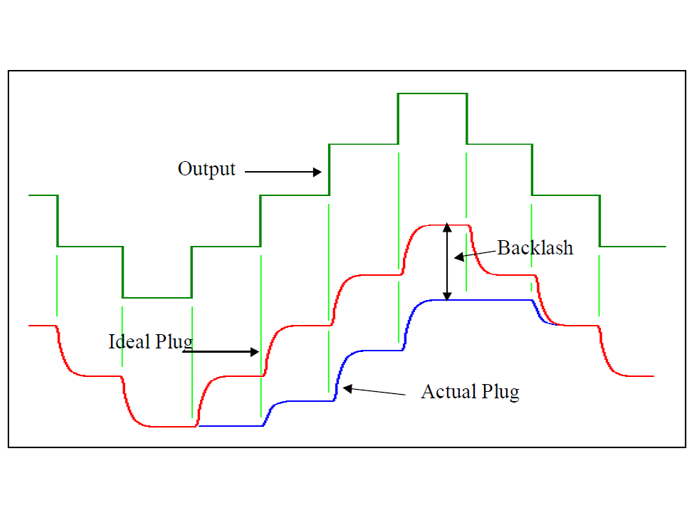

- Advanced Troubleshooting

Tyler Rushfeldt has over 10 years experience across various aspects of the pipeline industry, notably steady state and transient hydraulics and currently specializing in pressure control applications

Doug Nelson has over 30 years of industrial process control experience and process control training of operators, E/I techs, and process control engineers.

No records found.

This two-day advanced course builds on the concepts presented in the two-day basics course. The course begins with a review of advanced strategies for pipeline pressure control (output linearization, split ranging). The applications, benefits, and challenges of flow control are the next main topic. Viscosity control (sensors, dynamics, control strategies) and advanced troubleshooting techniques are the final topics.

Approximately 40% of the course is devoted to a computer-based lab. The labs focus on developing an understanding of the costs/benefits of advanced strategies, the application of Lambda tuning to these strategies, and troubleshooting complex control logic.

The course is primarily intended for process control engineers, operations engineers, and experienced instrument and electrical technicians. The Pipeline Process Control Optimization basics course (or equivalent) is a prerequisite for attendance. The course explores the implications of process equipment design on control performance and would be beneficial for maintenance and design engineers.

The course is conduct by video conference.