High process variability compromises the economic performance of continuous processes. A control loop that is well designed, maintained, and tuned can play a key role in minimizing process variability. Unfortunately the control loop often acts to increase process variability due to poor valve response, oscillatory controller tuning, and sensor problems.

The instrumentation technician who is given the responsibility of maintaining control loop health and optimizing controller tuning sometimes has little or no formal training in these activities. Tuning the controller by guesswork is a frustrating experience, often resulting in little or no improvement in control loop performance.

The process control optimization course will provide the tools to identify and correct process control problems using sound engineering principles.

The course is conducted at a hotel conference facility. The class size is limited to 8 students.

Topics covered include:

- Role of the Control Loop

- DCS Overview

- Process Dynamics

- Non-linearities

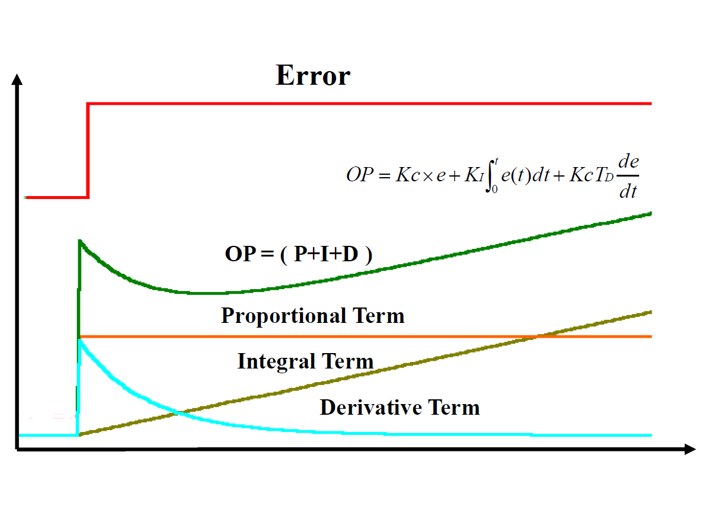

- PID Controller

- Lambda Tuning Procedures

- Setpoint and Load response

- Advanced regulatory control strategies

- Developing Tuning strategies

- Troubleshooting Loop Problems

Tyler Rushfeldt, P.Eng. has over 10 years’ experience across various aspects of the pipeline industry, notably steady state and transient hydraulics and currently specializing in pressure control applications.

Doug has over 30 years of industrial process control experience. He has authored papers on loop monitoring systems, control valve selection and the uses of process simulation in optimization surveys.

No records found.

This four-day course is intended to strengthen the student's ability to optimize control loop performance. Control loop fundamentals, the measurement of process dynamics, and Lambda tuning are the key topics in the first half of the course.

The second half of the course focuses on control loop performance, applying Lambda tuning to advanced regulatory control strategies, and analytical control loop troubleshooting.

Approximately 40% of the course is devoted to a computer-based lab that illustrates the main concepts.

The course is primarily intended for E&I mechanics, instrumentation engineers, and process engineers. It is also a good introductory course for process control specialists.

The course is being held at a conference facility. Attendees are responsible for arranging their own accommodations.

For convenience, we recommend that registrants stay at the hotel course site.